Eco-friendly synthetic leather

The following conditions need to be met:

Do not use animal skins as raw materials

The product is environmentally friendly and does not contain DMF, o-benzene, PAH, APEO, azo, PBA and other harmful chemicals

No volatile organic compound emissions (zero VOC emissions)

The production process is environmentally friendly, no pollution, no toxic and harmful waste gas and wastewater discharge

Follow a sustainable development strategy

GRCN products can meet all the conditions of eco-friendly leather. Click the link below to get more product information.

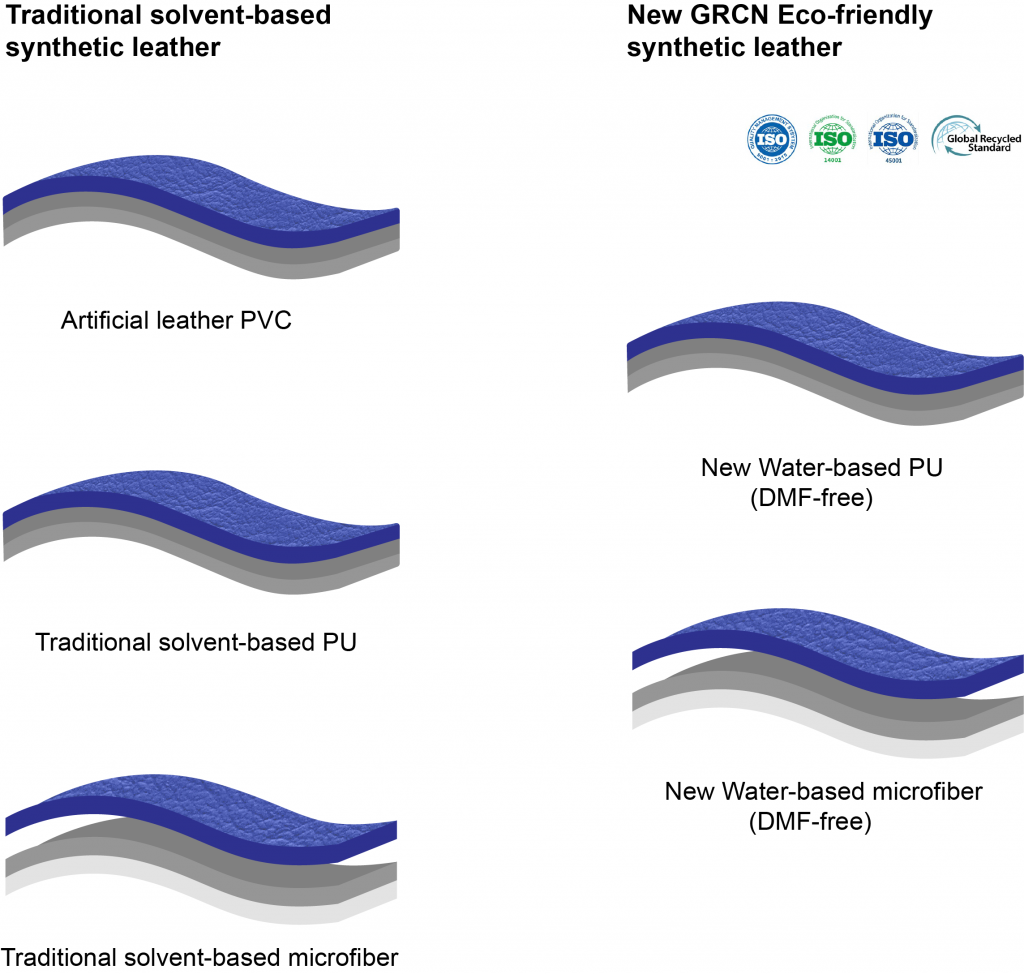

Types of synthetic leather on the market

Artificial leather (PVC):

Usually we refer to artificial leather, which is PVC. PVC artificial leather is the earliest product that imitates genuine leather. It is called polyvinyl chloride artificial leather. It has poor performance and is not environmentally friendly.

PVC products contain some toxic additives and plasticizers, which may ooze or vaporize. Some additives will interfere with biological endocrine (affecting reproductive function), and some will increase the risk of cancer.

PVC products have poor air permeability and become hard in low-temperature environments, resulting in poor bending performance and causes cracks. The advantage is that the product is cheap, and the surface abrasive resistance is high. At present, most of the low-end products use PVC.

Synthetic leather (PU):

PU is short for polyurethane. PU leather is synthetic leather made from polyurethane.

Because the physical properties of PVC products are affected by temperature, they are unstable,and the PVC pollution is serious. So that it can’t meet the requirements of social development and the commodity market more and more. Therefore, PU synthetic leather was invented.

There are two types of polyurethane synthetic leather on the market: Traditional Solvent-based polyurethane synthetic leather and new Water-based polyurethane synthetic leather.

Traditional solvent-based polyurethane leather is synthetic leather made of DMF as the main raw material, which also contains other toxic and harmful chemicals, such as toluene, xylene, acetone, etc. Products made from traditional solvent-based PU leather will cause harm to the environment and human body due to the residue and volatilization of DMF, DOP, and other substances. Moreover, its production process is not environmentally friendly, and a large amount of waste gas and wastewater will be generated during the production process, and most of the pollutants cannot be treated properly, causing serious pollution to the environment.

DMF is easily absorbed through the skin and may cause liver damage and other adverse health effects. According to REACH regulations, DMF is classified as a substance of very high concern (SVHC) and classified as toxic to reproduction (according to Regulation (EC) No. 1272/2008, Reproductive Toxicity Cat 1B).

The new Water-based polyurethane synthetic leather is made of waterborne polyurethane as the main raw material, and the waterborne polyurethane is made of water instead of organic solvent DMF. The product is environmentally friendly, non-toxic, no peculiar smell, DMF-free, toluene-free, etc., and is harmless to the human body. In addition, the production process of waterborne polyurethane synthetic leather is environmentally friendly, there is no harmful waste gas or wastewater discharge. It is a product that conforms to the sustainable development strategy and can meet various standards related to synthetic leather issued by various countries.

Waterborne polyurethane synthetic leather also has excellent physical properties, such as high peeling, high folding resistance, and high abrasion resistance. It can be widely used in shoemaking, luggage, apparel, car interiors, home furnishing, packaging, and sports goods, etc.

For more information about waterborne polyurethane synthetic leather, please click the link below

Microfiber:

The full name of microfiber is microfiber polyurethane synthetic leather, which is the highest quality synthetic leather.

The surface layer of the microfiber synthetic leather is composed of a polyurethane layer similar to the grain surface layer of natural leather, and the base layer is made of microfiber non-woven fabric, and its structure is very similar to the mesh layer of natural leather. Therefore, microfiber synthetic leather has a very similar structure and performance to natural leather. Its thickness uniformity, tear strength, color vividness, and product utilization are better than natural leather, and it has become the development direction of contemporary synthetic leather.

Microfiber leather includes traditional solvent-based microfibers and new Water-based microfibers.

Traditional solvent-based microfibers use solvent-based resins containing DMF as raw materials, and a large amount of wastewater containing DMF is generated during the production process, causing serious environmental pollution and resource waste, making traditional solvent-based microfibers not up to environmental standards. In addition, toluene remains in the final product and has a pungent odor. Therefore, traditional solvent-based microfibers are not suitable for long-term development.

The production of new Water-based microfibers uses waterborne polyurethane resin as raw materials, the production process is environmentally friendly, the finished product is non-toxic and harmless, and has extremely excellent physical properties. The water-based microfiber synthetic leather strictly follows the highest standards from the raw materials to the production process, and to the finished product, which fundamentally solves the environmental protection problem of microfiber synthetic leather. It conforms to people’s pursuit of ecology and environmental protection, and it also conforms to the sustainable development strategy.

For more information about Water-based microfiber products, please click the link below

While vigorously developing the economy, maintaining a good environment and a healthy body is an important goal of the sustainable development of society. Correctly handling the relationship between “environment” and “economy” and reducing industrial production’s harm to the environment and humans is an unstoppable trend and our responsibility. Mankind has only one earth. It has become a global consensus to protect its homeland and maintain sustainable economic development, which has attracted the attention of governments of all countries. At present, major synthetic leather producing countries such as the United States, Italy, Japan, South Korea, and China have gradually phased out traditional solvent-based synthetic leather and adopted new environmentally friendly synthetic leather.

GRCN’s goal is to create sustainable fashion, bringing attractive and eco-friendly materials. Improve the quality of customer service and implement more efficient supply chains. GRCN promise every series compliance with environmental standards.

Related legislation:

The European Reach Regulation Candidate List was updated on January 19, 2021, and the SVHC list was officially updated to 211 substances of very high concern. These include dimethylformamide (DMF), toluene, etc., which are commonly used raw materials for solvent-based synthetic leather.

On October 27, 2017, the World Health Organization Cancer Research Institute declared DMF as a Class 2A carcinogen.

ZDHC international organization “Zero Discharge of Hazardous Chemicals” has joined with many internationally renowned brands to propose the concept of “environmental protection in the industrial chain”, and at the same time formulated the “Restricted Substances List” in the production process and promised “zero emissions of hazardous chemicals (VOC) in 2020″.